Arrival of the New NMR Spectrometer

We recently received a grant from the National Science Foundation (CHE-0521075) for a new NMR spectrometer. The system we chose is a Bruker Avance II 400 MHz spectrometer system. The magnet is a 9.4T superconducting solenoid and the cryostat has exactly the same dimensions as our prior 250 MHz magnet. The system was delivered in early March of 2006. Prior to that, the existing room was renovated, following decommissioning of our old AC-250 system.

For those who have not seen the installation of such an instrument before, it is rather an interesting process. First, the system arrives in rather a large number of boxes (the tall one in the back is the magnet).

Just before installation, the cryogens arrive (much more than one might be used to, under normal circumstances). It requires almost all of this to cool the cryostat so that the magnet can be brought to field.

The magnet is then placed in its desired location using a tripod assembly and assembled. Placement of the magnet is critically important due to the stray field and potential for electronic, radio, and vibrational disturbances.

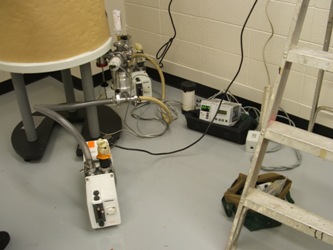

The seals are put in place and the vacuum space evacuated to 10-6 torr using a turbo pump similar to those used in mass spectrometers.

This high level of vacuum is for insulation purposes. Otherwise the expensive liquid helium (LHe) would boil off far faster than the six month fill interval for which cryostat is rated. Once the magnet has been evacuated, it is ready for filling with cryogens. First, both dewars are precooled with boiloff from a liquid nitrogen tank to bring the system to 77 Kelvin. Then the outer dewar is filled with liquid and the nitrogen gas in the inner dewar is removed and purged with helium gas prior to filling with LHe. The precooling step reduces the amount of expensive LHe required to fill the inner dewar. Once the LHe is filled, the system is allowed to cold soak for a few days to equilibrate before the magnet is charged. At this temperature, a normal thermometer would be ineffective, so the temperature is determined indirectly through measurement of the coil resistance as can be seen in the picture below.

The magnet charging process is quite a delicate matter, as the coils must be brought to a current of around 100 amperes to create the field. The superconducting wire has a copper insulating jacket and a superconducting core of an alloy of niobium and titanium. An individual filament has a diameter of a little more than a human hair, and the coil length is several kilometers. Some examples of superconducting wire are shown below.

In order to bring the magnet to field, current is slowly added to the coils by means of a heated shunt, which allows current to be added or bled off, much as was shown in the decommissioning of our previous magnet. The current is fed in slowly (below) over the course of about two hours to avoid inadvertently quenching by causing movement of the coils (a mechanical effect of the internal field) or by thermal quenching.

Even though a minimum of heat is required for the bypass shunt, this process boils off a fair amount of helium as can be seen from the frost on the vent stacks (below).

Although our new magnet has much higher internal field, it has no more stray field than our prior magnet as it is actively shielded. That is, it has an opposing solenoid in the outer portion of the magnet to reduce the amount of stray field that passes into the room. This reduces the stray field to about half what it would otherwise be. This allows the magnet to be positioned closer to the walls without posing a magnetic hazard to persons on the other side. This also allows us much more space in the magnet room.

The new system is also equipped with an automatic sample changer, which allows us to run samples in automation, thus making more efficient use of instrument time, and allowing unattended overnight and weekend acquisitions.

Jennifer Inlow, Chairperson

email:jennifer.inlow@indstate.edu

Department of Chemistry and Physics

600 Chestnut Street

Science Building, Room 035

Indiana State University

Terre Haute, IN 47809

Chemistry

Office: Science 035

Phone: 812-237-2239

Fax: 812-237-2232

Physics

Office: Science 165

Phone: 812-237-2239

Fax: 812-237-4396

Office Hours

Monday-Friday

8:00 AM - 4:30 PM

Driving Directions